See how warehouse teams actually use LollipopWMS

Walk through real screens—from receiving dock to shipping manifest—and see how scan-first workflows keep accuracy high and training time low.

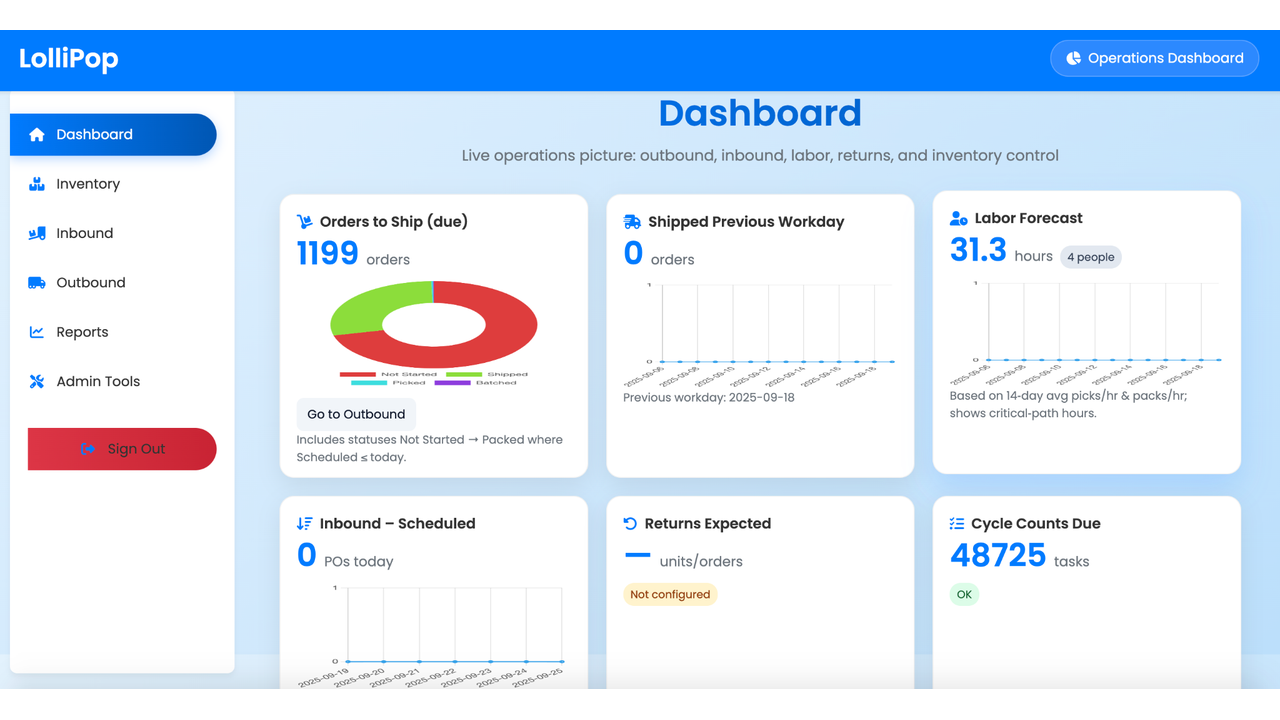

Operations dashboard

Start each day with a single view of what matters: orders to ship, labor forecast, cycle counts due, and any exceptions that need attention.

- Real-time order health scores by priority and SLA

- Labor productivity metrics across shifts

- Quick actions to reassign work or escalate issues

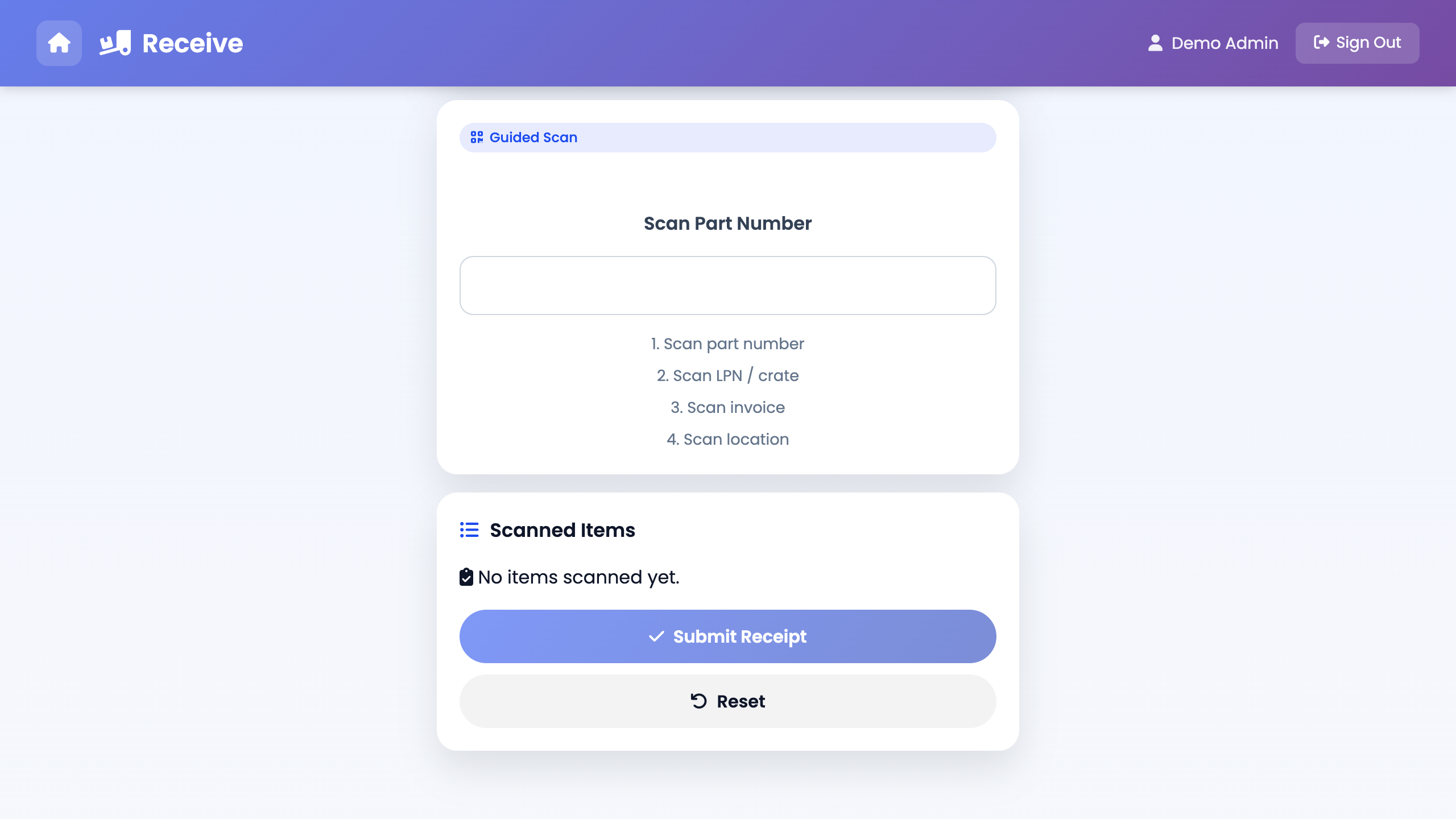

Receiving inventory

Dock teams scan inbound shipments against POs or receive without paperwork. Every unit gets tracked from the moment it hits the dock.

- Match receipts to purchase orders or ASNs

- Log damages, shortages, and overages with photos

- Print receiving labels and route to QC if needed

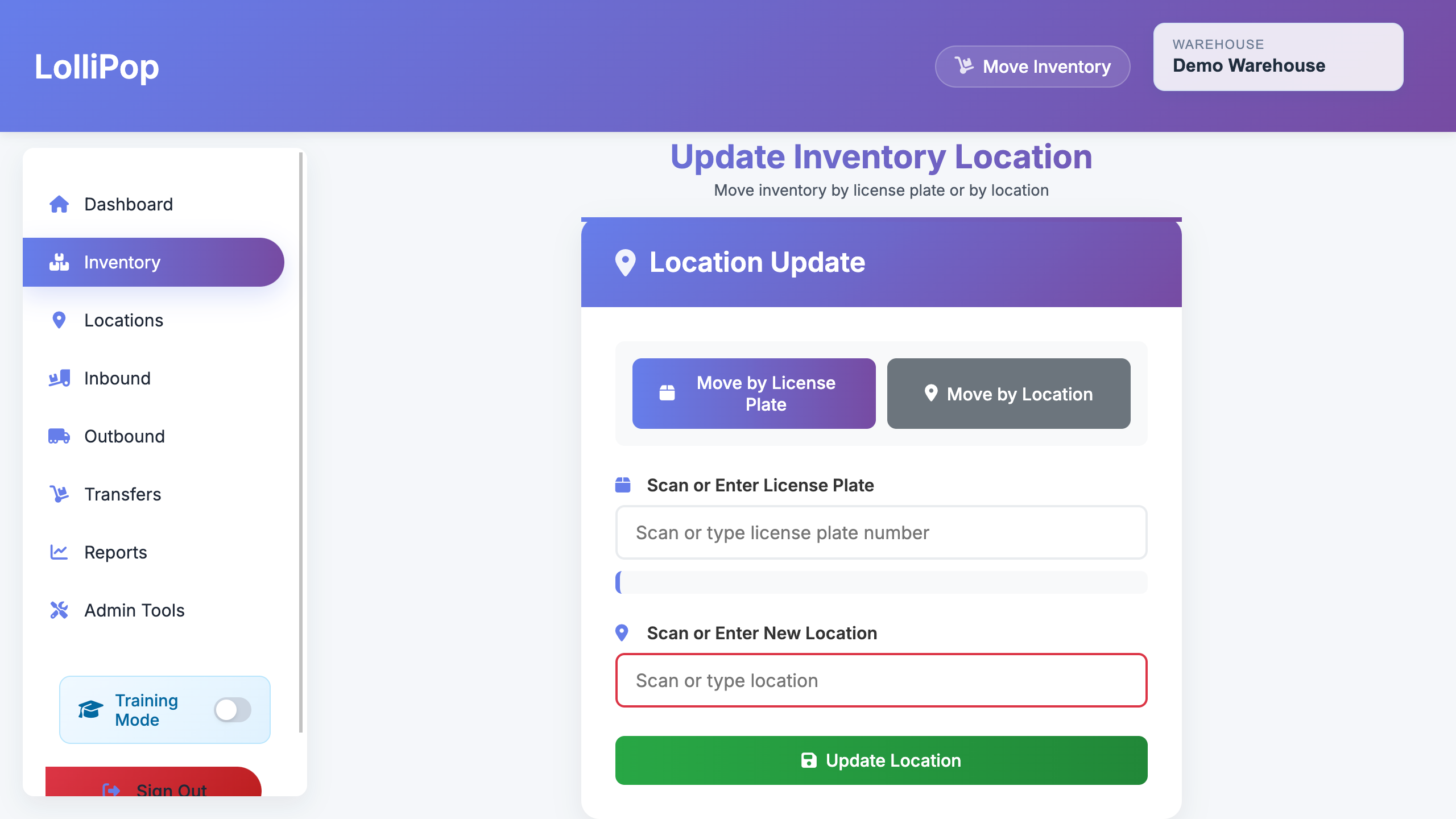

Directed putaway

After receiving, the system suggests optimal locations based on velocity, size, and zone rules. Associates scan to confirm placement.

- Smart location suggestions based on pick frequency

- Scan-to-confirm prevents misplacements

- Override suggestions when needed with audit trail

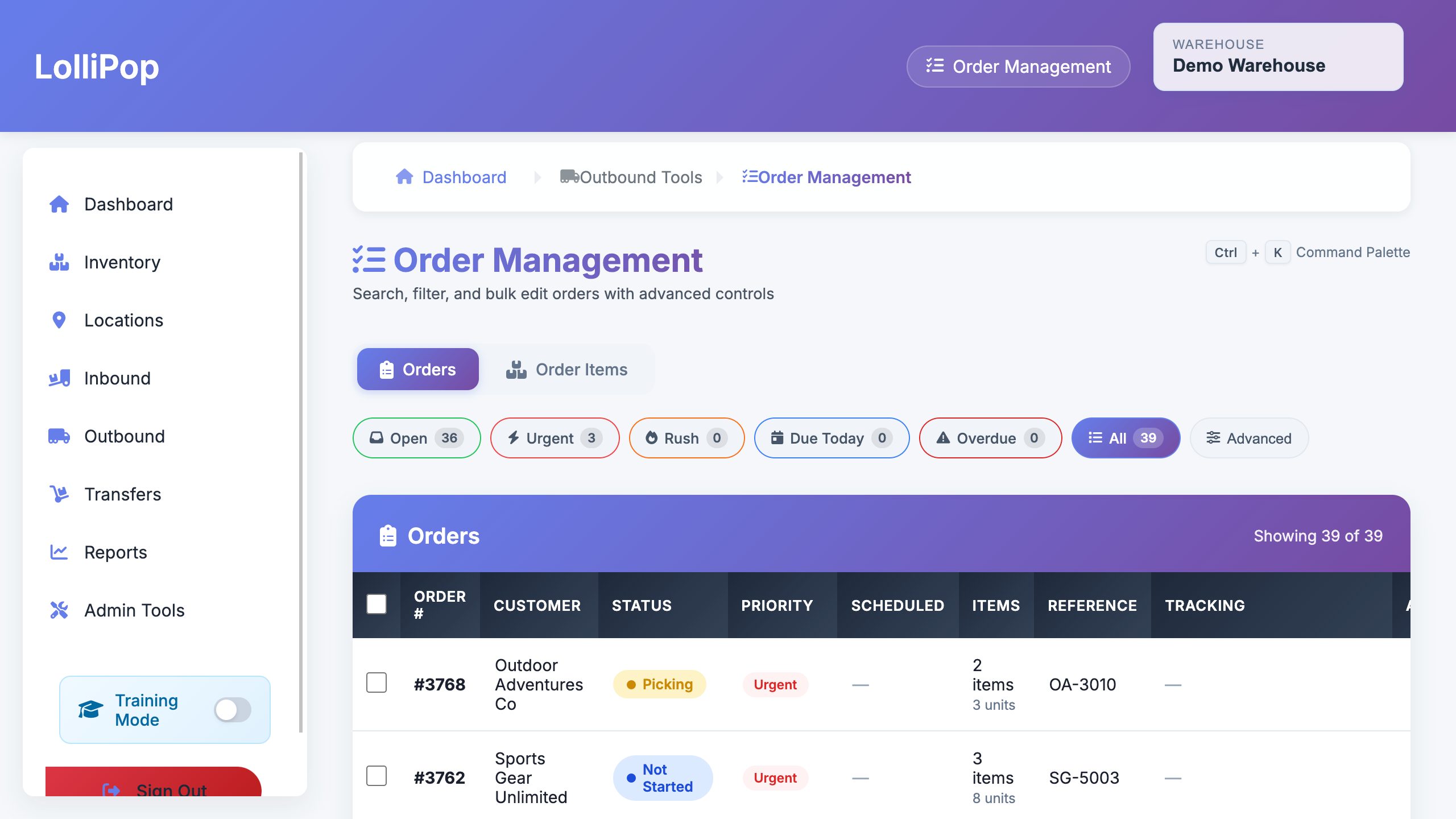

Order management

See every order across all channels in one queue. Filter by status, priority, or carrier cutoff. Release to picking with one click.

- Unified view of Shopify, Amazon, and manual orders

- Priority badges and SLA countdown timers

- Bulk actions for wave release and carrier assignment

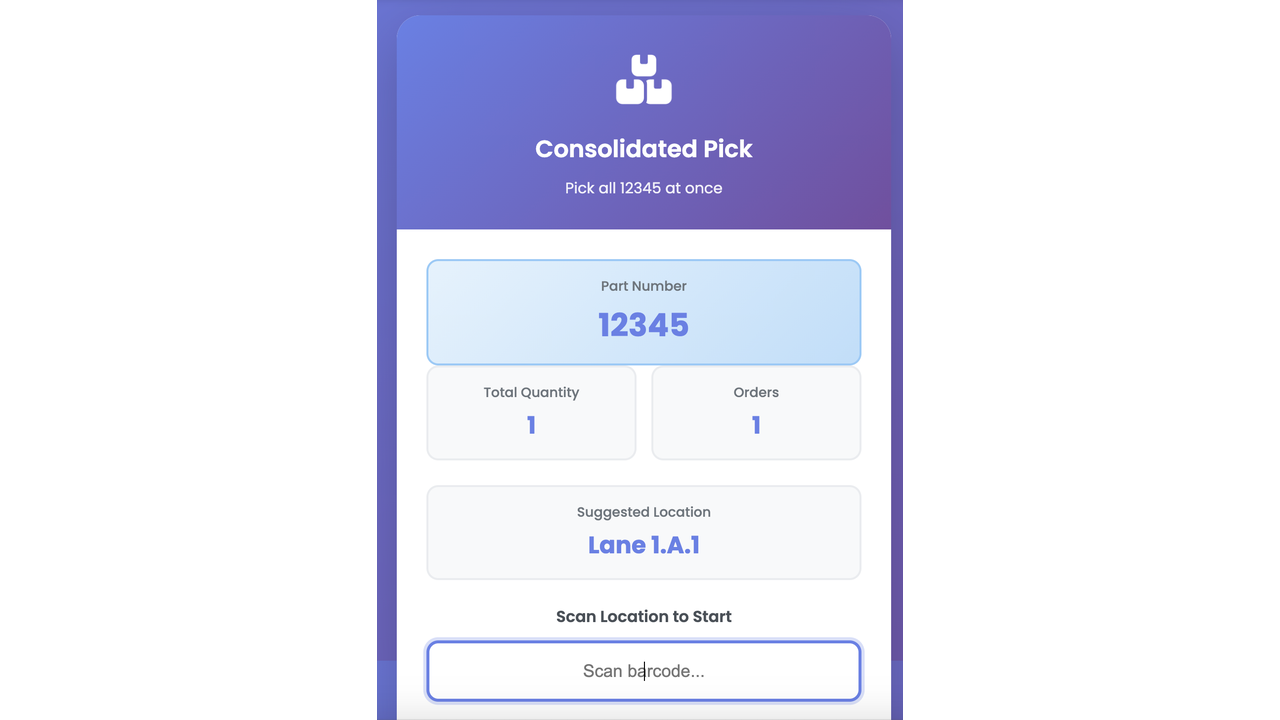

Batch picking

Pick multiple orders in a single trip. The system optimizes routes and tells associates exactly where to go and what to grab.

- Route-optimized pick paths reduce walking by 35%

- Scan verification prevents mispicks

- Handle short picks and substitutions in-flow

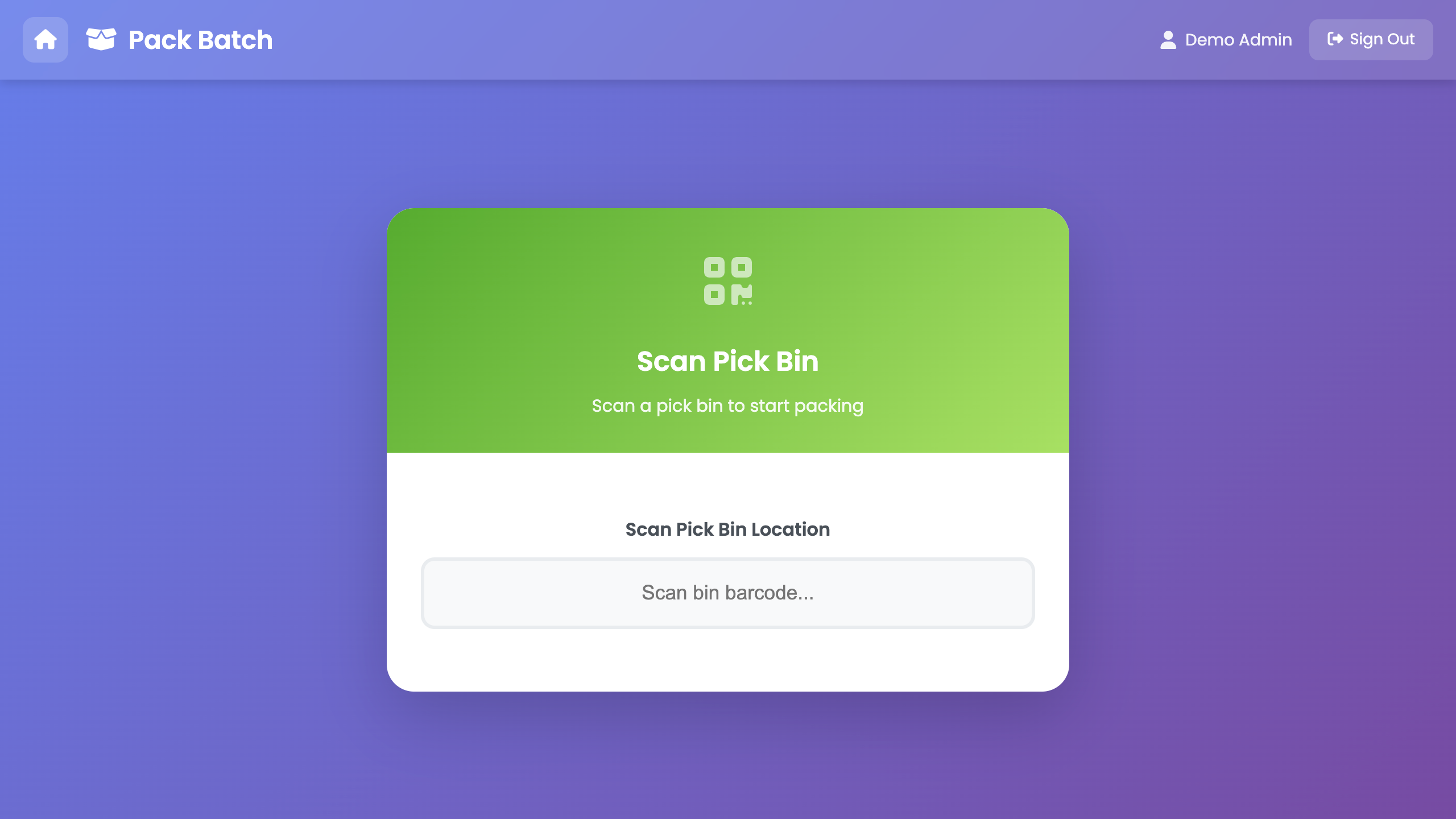

Pack & ship station

Packers scan the pick bin, verify contents, select packaging, and print carrier labels—all without switching apps.

- Verify order contents with scan confirmation

- Rate shop across carriers or use preset rules

- Print labels, packing slips, and customs docs together

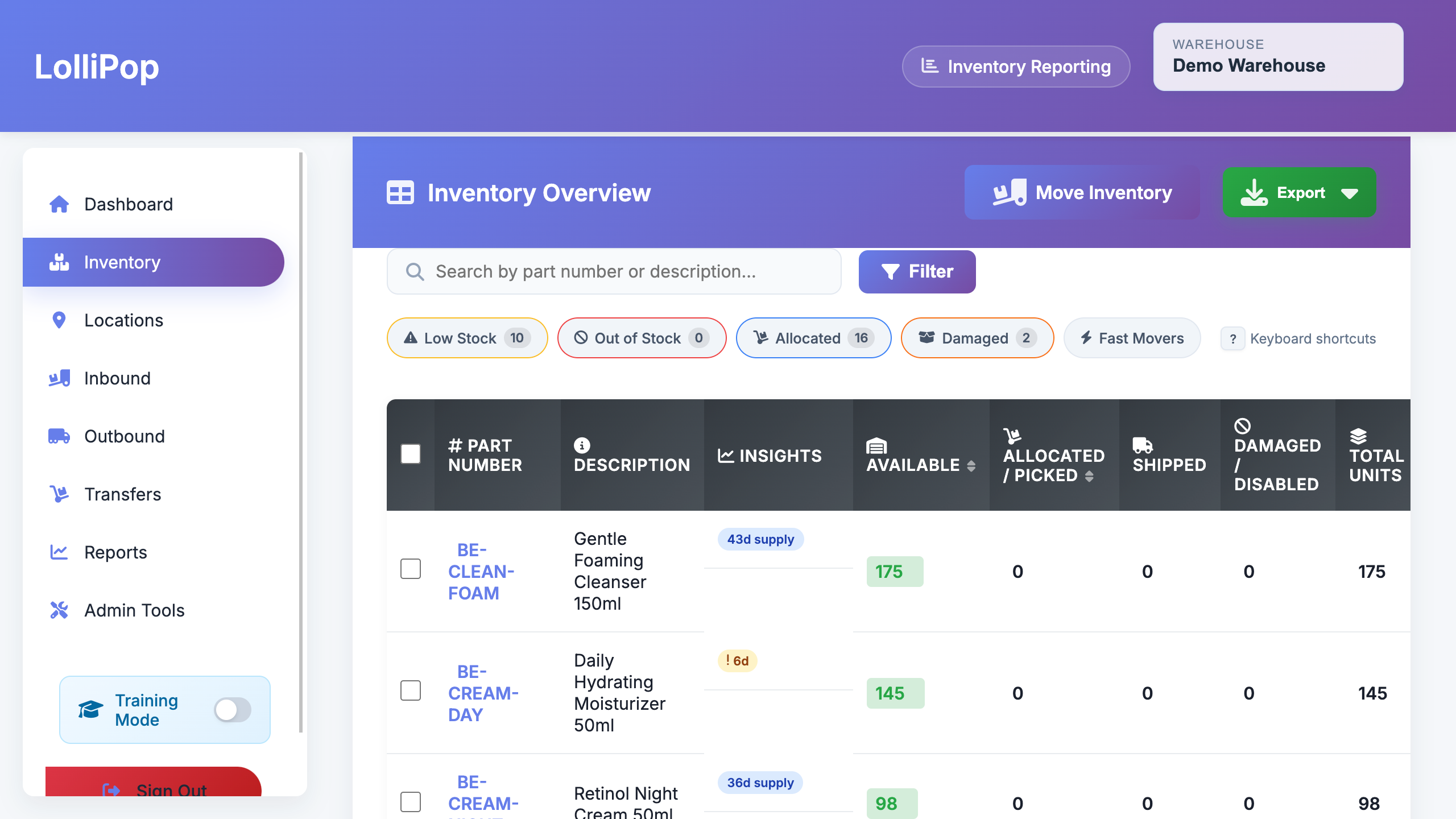

Inventory visibility

See every SKU across every location. Filter by status, location, lot, or customer. Adjust quantities with full audit trail.

- Real-time inventory grid with advanced filters

- Drill into location, lot, and serial details

- Adjust, move, or hold inventory with reason codes

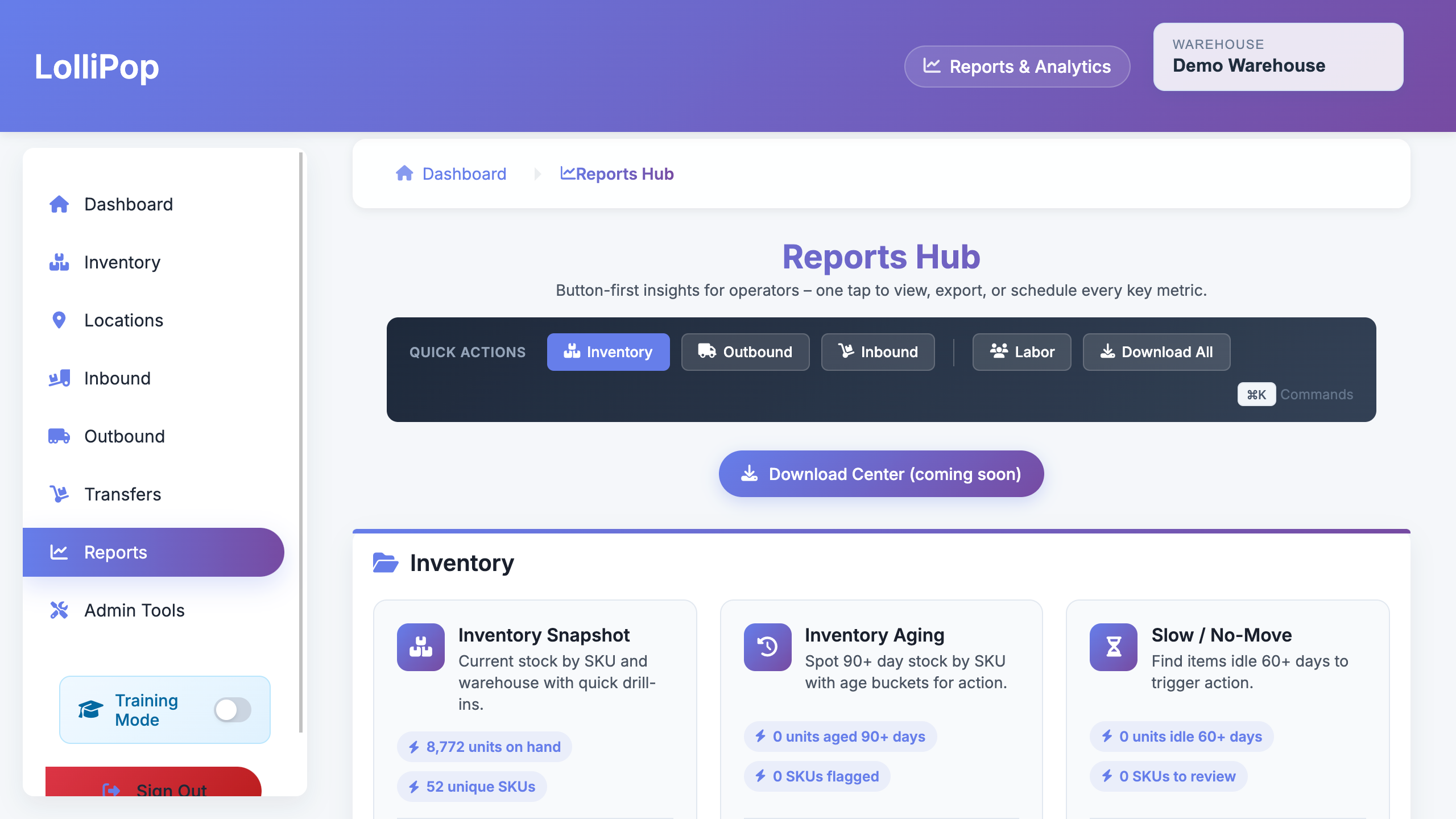

Reporting & analytics

Track performance over time with built-in reports. Export to CSV or schedule automated delivery to stakeholders.

- Order accuracy, throughput, and cycle time trends

- Labor productivity by associate and shift

- Inventory aging and velocity reports

Ready for a deeper dive?

Join a founder-led walkthrough or launch your own sandbox and explore with real data.