Wave Picking Playbook

Sequence waves by carrier cutoffs, zone, and service level to keep docks flowing.

Design multi-order batches that shorten walking paths and speed fulfillment.

Standardize batch picking with workflows, metrics, and coaching prompts your team can trust.

Use batch picking when you ship 50+ orders per day and want to reduce walking time by picking multiple orders in a single trip through the warehouse.

Follow these steps to configure batch picking optimization in your warehouse.

Group orders by zone, carrier, or priority to create optimal batches

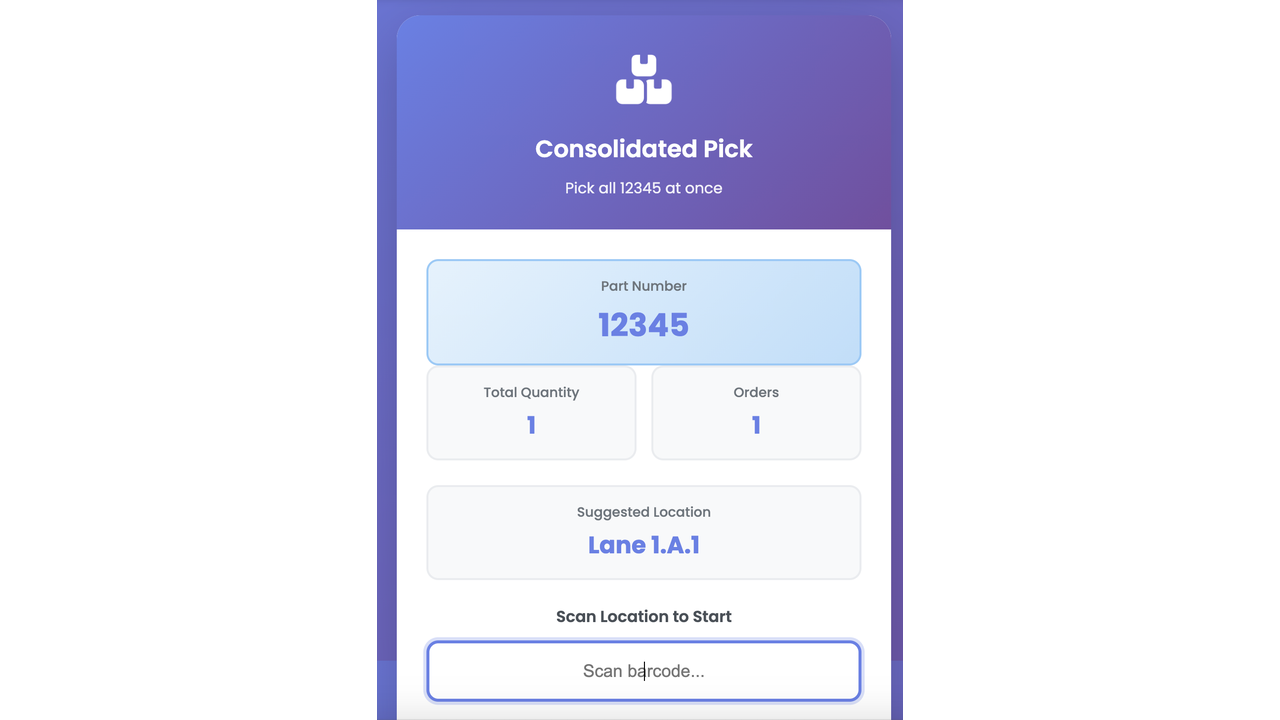

Print batch pick list or push to mobile device with route optimization

Pick items into totes or a cart, scanning each item for verification

Sort picked items to individual orders at the pack station

Reduction in walking time

Lines picked per hour

Pick accuracy with scanning

Lessons learned from successful implementations.

Most teams start with 3–5 orders per cart and scale once quality stays above target.

Yes. Tag orders by client or channel and apply routing rules to respect branding requirements.

The handheld flags the exception, prompts for substitution, and sends an alert to supervisors for follow-up.

Start your free trial and configure this workflow in minutes.