Batch Picking Optimization

Design multi-order batches that shorten walking paths and speed fulfillment.

Orchestrate packing stations, label printing, and manifest creation from one screen.

Standardize pack and ship with workflows, metrics, and coaching prompts your team can trust.

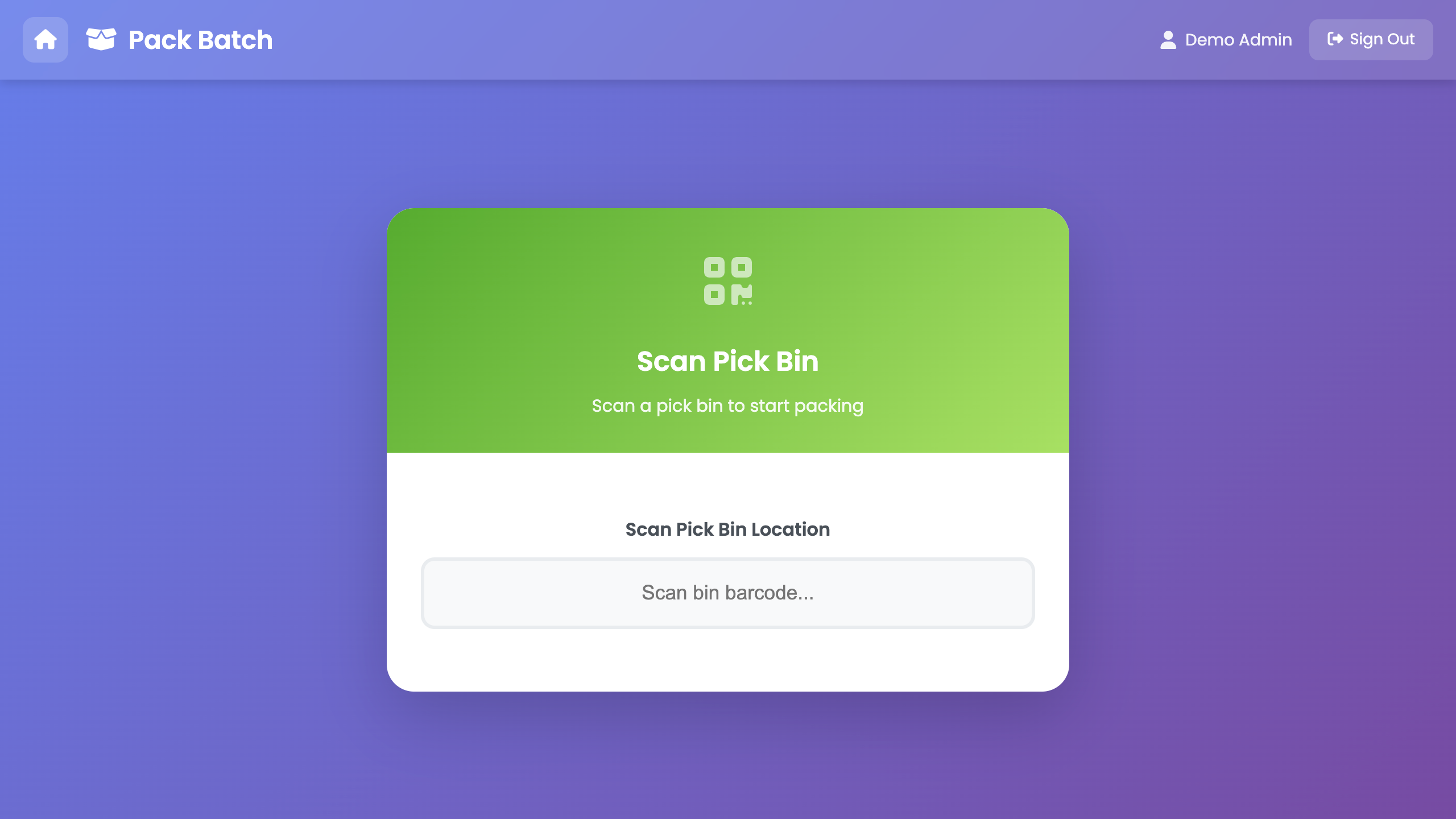

Use the packing station workflow to verify orders before shipping and print carrier labels directly from the WMS.

Follow these steps to configure pack, ship & label automation in your warehouse.

Scan order or pick tote to open packing station

Scan each item to verify against order - system alerts on mismatches

Select packaging and enter dimensions/weight if not preset

Print carrier label - rate shop or use preset carrier rules

Ship accuracy with scan verification

Label cost savings with rate shopping

Average pack time per order

Lessons learned from successful implementations.

Yes. Search by order, tote, or tracking number and reprint with original contract terms.

Order-specific notes, gift messages, and packaging instructions appear during verification.

Manifest close-outs auto-generate once batches finish. Operations can download PDFs or send digital versions to carriers.

Start your free trial and configure this workflow in minutes.