Batch Picking Optimization

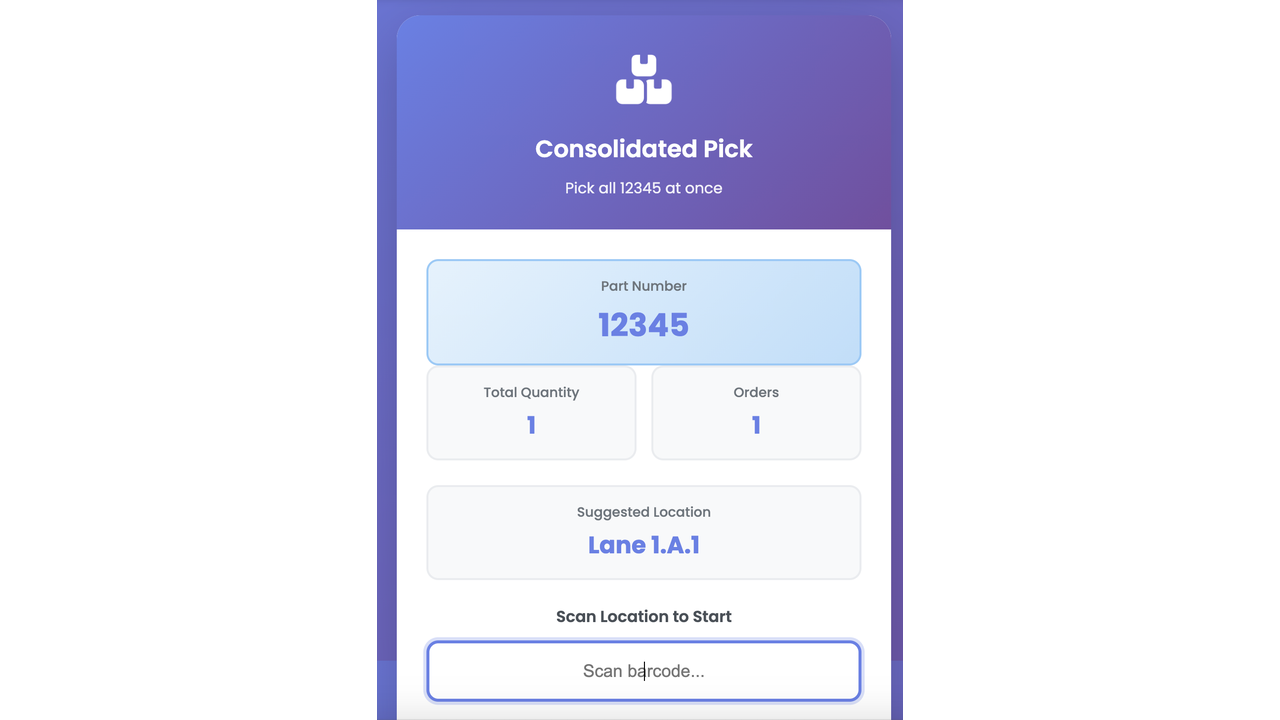

Design multi-order batches that shorten walking paths and speed fulfillment.

Build kitting and light assembly stations with scanned instructions.

Standardize kitting with workflows, metrics, and coaching prompts your team can trust.

Use pre-kitting when you need to build finished products from components before orders arrive - common for subscription boxes, gift sets, and bundled products.

Follow these steps to configure pre-kitting workflows in your warehouse.

Define kit BOM (bill of materials) with component quantities

Create work order to build specified number of kits

Pick components to assembly station

Build kits, scan finished product, and receive to inventory

Faster order fulfillment vs. pick-to-order kitting

Component tracking through assembly

Average kit assembly time

Lessons learned from successful implementations.

Yes. Disassembly workflow returns components to inventory with proper quantity adjustments.

Configure alternate components in the BOM. System prompts for substitution when primary component is unavailable.

Finished kit inherits lot/serial from components. Full traceability from component receipt through kit shipment.

Start your free trial and configure this workflow in minutes.