Cycle Counting Control

Automate cycle count waves and reconcile variances before they reach the customer.

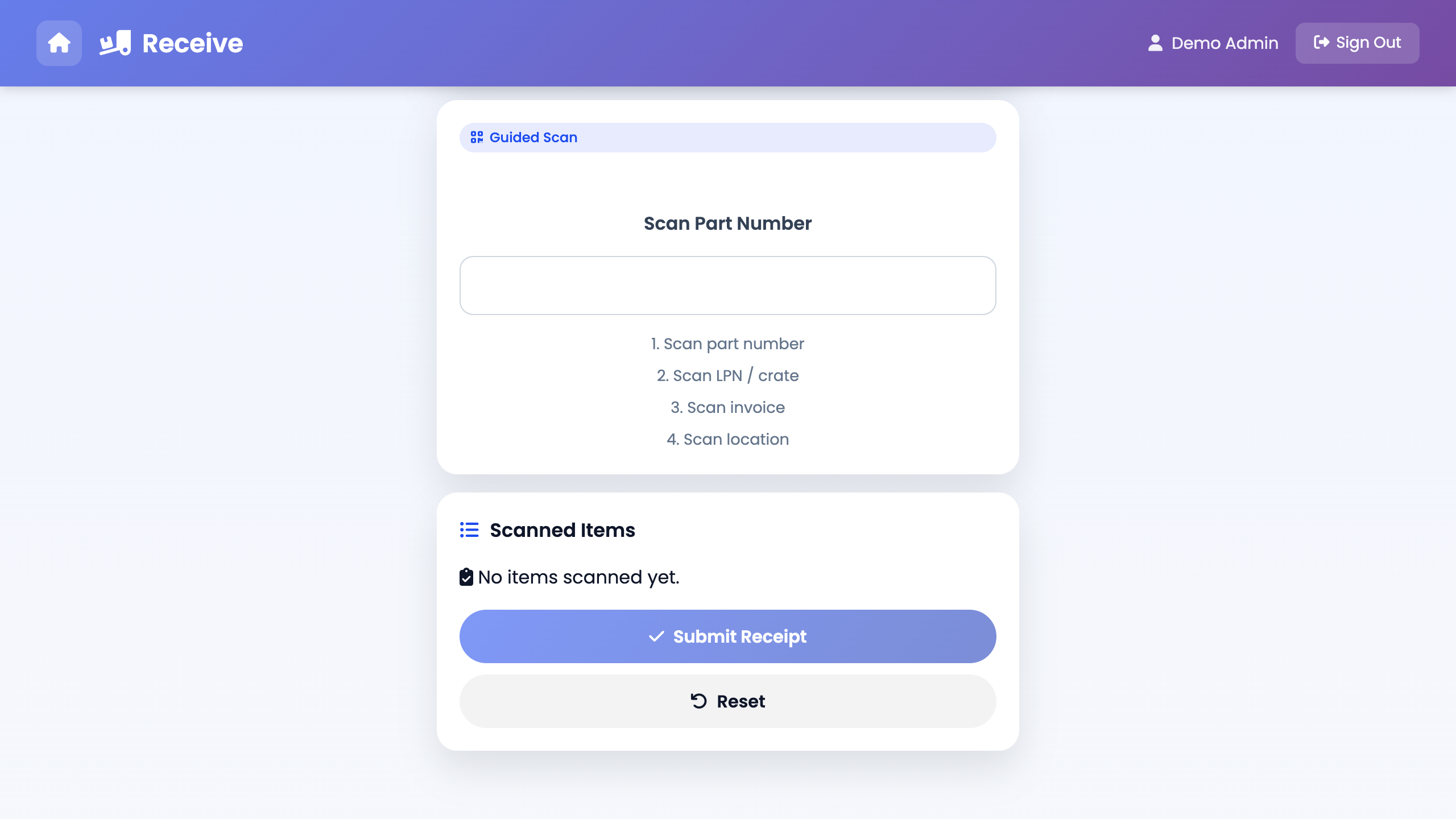

Guide teams through dock receiving, inspection, and smart putaway suggestions.

Standardize receiving with workflows, metrics, and coaching prompts your team can trust.

Use structured receiving when you need to verify incoming shipments against purchase orders and direct inventory to optimal storage locations.

Follow these steps to configure receiving & putaway control in your warehouse.

Scan or select purchase order when shipment arrives

Receive items with barcode scanning and quantity verification

System suggests optimal putaway locations based on velocity and slotting

Confirm putaway by scanning location barcode

Dock-to-stock time

Receipt accuracy with scanning

Faster picks with optimal slotting

Lessons learned from successful implementations.

Yes. Build ad-hoc receipts, capture counts, and generate labels on the spot.

Configure cross-dock rules to bypass storage locations and send product straight to staging.

Reliable coverage is recommended. Offline modes buffer transactions until devices reconnect.

Start your free trial and configure this workflow in minutes.