Batch Picking Optimization

Design multi-order batches that shorten walking paths and speed fulfillment.

Capture dispositions, recoup inventory, and trigger refunds without silos.

Standardize returns with workflows, metrics, and coaching prompts your team can trust.

Use returns processing when you receive customer returns and need to inspect, grade, and route items to appropriate inventory or disposal.

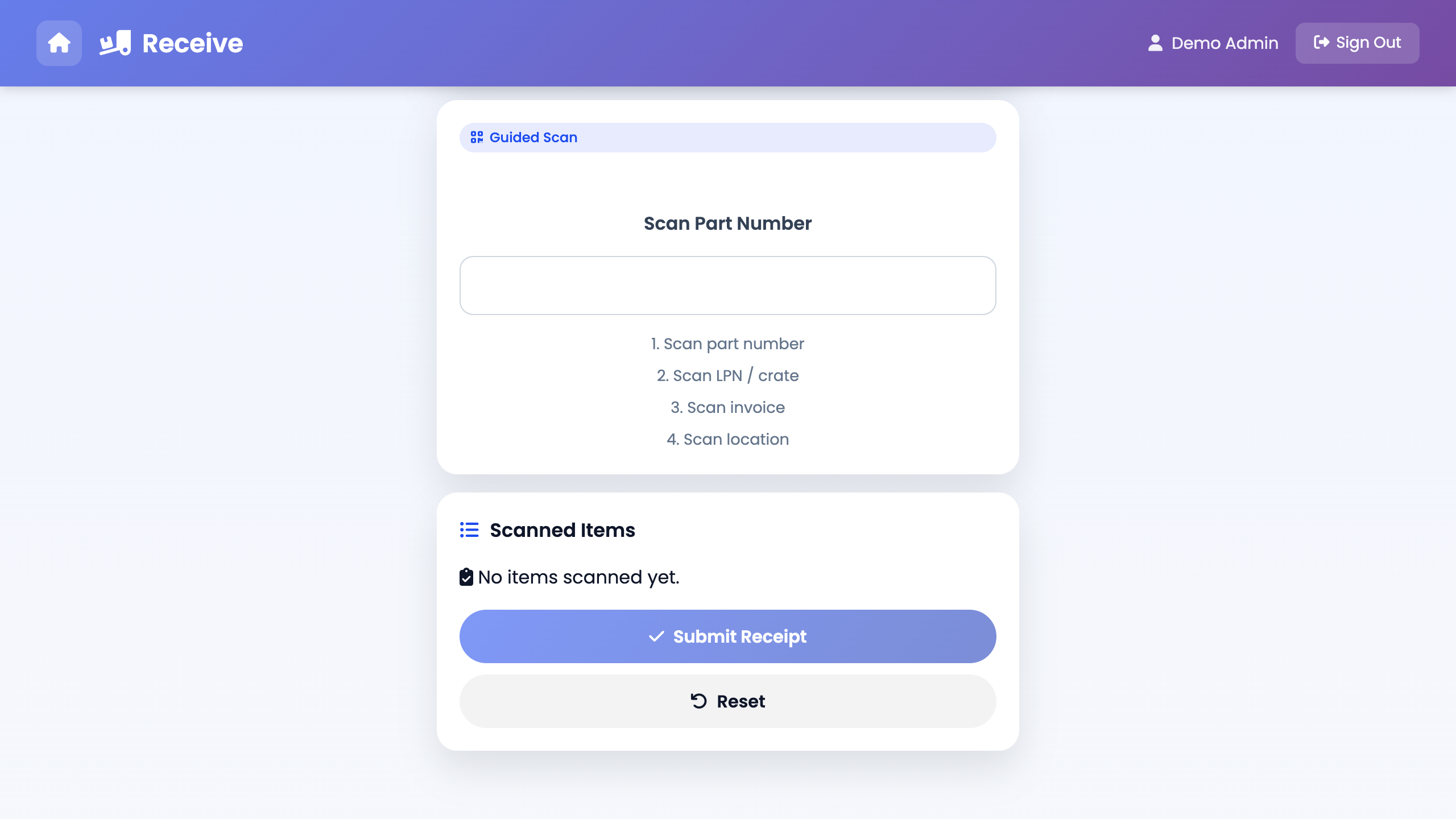

Follow these steps to configure returns processing control in your warehouse.

Create or scan RMA to open return receipt

Inspect each item and assign condition code

Route sellable items to inventory, damaged to hold

Process refund or exchange based on inspection

Return processing time

Items returned to sellable inventory

Return reason tracking

Lessons learned from successful implementations.

Process the return, then create a new order for the exchange item. Links both transactions for reporting.

Yes. Capture reason codes during inspection. Reports show trends by product, customer, and carrier.

Configure fee rules by condition or reason. System calculates and applies fees automatically.

Start your free trial and configure this workflow in minutes.